ProQual NVQ Level 3: Diagram & Photo Interpretation Guide

Table of Contents

Construction sites are dynamic environments where hazards, defects, and non-compliance can occur at any stage. Inspectors, supervisors, and engineers must be able to observe and interpret site conditions accurately, identify risks, and recommend corrective actions to ensure safety, quality, and compliance.

This task focuses on photo and diagram interpretation. Learners will study assessor-provided site images or technical diagrams showing work activities, equipment, and materials. They will analyze potential hazards, operational defects, or regulatory non-compliances and provide professional recommendations.

The exercise develops:

- Observation and analytical skills.

- Application of UK construction laws and regulations.

- Decision-making skills for corrective actions.

- Documentation and reporting skills.

Key UK regulations relevant to this task include:

- Health and Safety at Work Act 1974 (HSWA) – general duties to ensure the safety of workers and the public.

- Construction (Design and Management) Regulations 2015 (CDM 2015) – planning, coordination, and risk management.

- Provision and Use of Work Equipment Regulations 1998 (PUWER) – safe use of equipment.

- Work at Height Regulations 2005 (WAHR) – safety for tasks at height, including scaffolds and ladders.

- Control of Substances Hazardous to Health (COSHH) 2002 – handling hazardous materials safely.

Observing Work Activities from Images and Diagrams

Observation is the first step in photo/diagram interpretation. Learners must:

- Examine all components of the image/diagram carefully.

- Identify work activities being performed.

- Note equipment, materials, and personnel involved.

- Detect any visible hazards or unsafe practices.

- Compare the scene to standard operating procedures and legal requirements.

Example Table – Observation Checklist

| Image/Diagram Element | Observed Activity | Equipment / Material | Potential Hazard | Regulation Reference |

| Scaffold in photo | Workers assembling | Scaffold sections, tools | Fall risk | WAHR 2005, CDM 2015 |

| Steel reinforcement | Inspecting bars | Ladders, PPE | Improper PPE use | HSWA 1974, PUWER 1998 |

| Electrical panel | Wiring installation | Tools, wires | Shock risk, exposed wires | HSWA 1974, CDM 2015 |

| Concrete mixer | Pouring concrete | Mixer, wheelbarrow | Machine malfunction | PUWER 1998 |

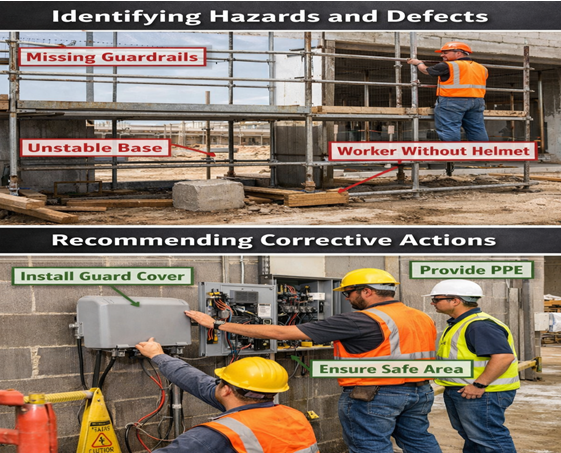

Identifying Hazards, Defects, and Non-Compliances

After observation, learners interpret the images/diagrams to identify:

- Health and Safety Hazards – risks to workers or the public.

- Equipment Defects – malfunctioning machinery or unsafe tools.

- Procedural Non-Compliances – tasks not following company SOPs or legal requirements.

- Environmental Risks – site conditions affecting safety (e.g., wet surfaces, poor lighting).

Example – Hazard Identification from Site Photo:

- Scaffold missing guardrails → fall hazard (WAHR 2005).

- Worker not wearing helmet → PPE non-compliance (HSWA 1974).

- Electrical wires lying on wet floor → electric shock risk (PUWER 1998).

- Concrete mixer unguarded → equipment hazard (PUWER 1998).

Tip for learners: Always link observed issues to the appropriate legal or procedural standard.

Recommending Corrective Actions

Once hazards, defects, or non-compliances are identified, learners must propose appropriate corrective actions.

Corrective Actions Should Include:

- Immediate measures to prevent accidents.

- Adjustments to work sequences or resource allocation.

- Repair or replacement of defective equipment.

- Reporting to supervisors and documenting corrective actions.

- Verification that corrective measures comply with UK regulations.

Example Table – Corrective Actions

| Observed Issue | Corrective Action | Priority | Reference |

| Scaffold missing guardrails | Install guardrails before use | High | WAHR 2005 |

| Worker without PPE | Issue helmet, gloves, and high-visibility vest | Immediate | HSWA 1974 |

| Electrical wires in wet area | Insulate wires, divert traffic, inform electrician | High | PUWER 1998 |

| Concrete mixer unguarded | Install safety guards, test equipment before use | High | PUWER 1998 |

| Materials blocking emergency exit | Clear exit, mark pathways | Immediate | HSWA 1974 |

Scenario-Based Exercises

Learners will study 4–5 site images or diagrams provided by the assessor. Each scenario requires:

- Observation: Note all activities, personnel, equipment, and materials.

- Interpretation: Identify potential hazards, defects, or non-compliances.

- Corrective Actions: Recommend professional actions to mitigate risks.

- Documentation: Record findings in a structured format for management review.

Sample Scenario 1 – Scaffold Inspection

- Photo shows workers erecting scaffolds with missing mid-rails and uneven base plates.

- Interpretation: High fall risk, unstable structure.

- Corrective Actions:

- Halt work until base is leveled.

- Install missing rails.

- Inspect scaffold according to WAHR 2005.

- Document inspection and notify site manager.

Sample Scenario 2 – Electrical Installation

- Diagram shows open electrical junction boxes near water containers.

- Interpretation: Shock hazard, non-compliance with PUWER 1998.

- Corrective Actions:

- Cover boxes with approved protective casings.

- Move water away from electrical area.

- Ensure electricians follow safe wiring practices.

- Record corrective actions and inspect daily until compliance.

Sample Scenario 3 – Concrete Pouring

- Image shows concrete mixer with exposed rotating parts and workers without gloves.

- Interpretation: Mechanical hazard, PPE non-compliance.

- Corrective Actions:

- Install machine guards.

- Issue PPE to all personnel.

- Conduct equipment safety briefing.

- Document actions for audit purposes.

Sample Scenario 4 – Material Storage

- Photo shows steel rods leaning unsafely against a wall, blocking access to fire exit.

- Interpretation: Trip hazard, fire safety risk.

- Corrective Actions:

- Store materials securely in designated racks.

- Clear pathways and mark emergency exits.

- Inspect storage weekly.

- Record in site safety log.

Learner Task

- Examine assessor-provided images or diagrams.

- Complete a photo interpretation table:

| Image/Diagram | Observed Activity | Hazard / Defect | Legal Reference | Recommended Corrective Action | Priority |

- Justify your recommendations using UK regulations and best practices.

- Prioritize actions based on risk severity.

- Submit a written report including:

- Observations and interpretations.

- Corrective actions with rationale.

- References to laws and regulations.

Submission Guidelines

- Minimum 3,000–4,000 words including tables and analysis.

- Submit in Word or PDF format.

- Include tables, bullet points, and flowcharts where applicable.

- Reference UK legislation: HSWA 1974, CDM 2015, PUWER 1998, WAHR 2005, COSHH 2002.

- Ensure professional language, clarity, and structured presentation.

- Highlight risk prioritization, compliance, and corrective actions.

Identifying Hazards and Implementing Corrective Actions