Master Photo / Diagram Interpretation Task Skills

Knowledge Providing Task: Photo/Diagram Analysis in ProQual Level 7

Table of Contents

Purpose

This task is designed to strengthen the learner’s ability to interpret real workplace situations using visual evidence. Senior health and safety leaders must often make decisions after reviewing site photographs, CCTV stills, equipment diagrams, digital dashboards, or inspection visuals. When analysing images, a strong safety culture depends on the ability to identify hazards, understand underlying causes, and recommend actions that support organisational sustainability and compliance.

This task trains the learner to interpret technical images in a structured way, link observations to relevant UK legislation, and propose corrective actions aligned with longterm health, environmental, and performance goals.

Each scenario below describes an image that the learner must analyse as though it were placed in front of them during an assessment.

SCENARIO 1 (LO1 – Digital Technologies and Safety Management)

Image Description

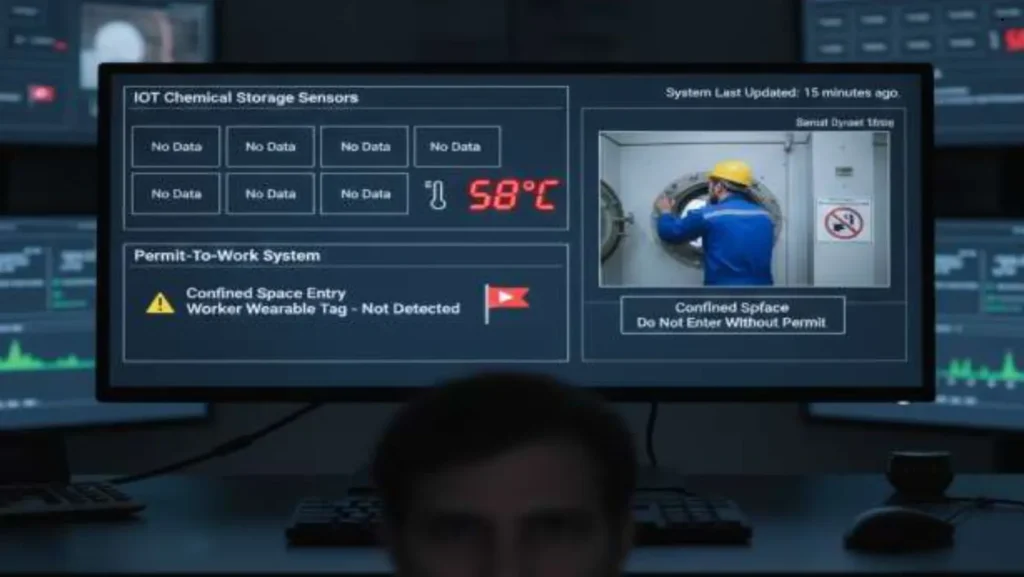

A digital control room screen displays a dashboard showing various real-time indicators.

In the picture:

- Several IoT sensors for a chemical storage area show “No Data”.

- One temperature reading is flashing red at 58°C.

- A digital permit-to-work panel shows a pending confined space entry, but the

worker’s wearable tag does not appear on the system. - CCTV feed shows the same worker already entering the confined space without

authorisation. - The system clock indicates the digital platform was updated only 15 minutes

earlier.

Interpretation Focus Areas

The picture presents failures in digital reliability, sensor communication loss, and culture issues leading to bypassed controls.

SCENARIO 2 (LO2 – Biohazards Risk Assessment and Controls)

Image Description

The image shows a laboratory corridor with:

- A sealed yellow clinical waste bin overflowing with used swabs and sample tubes.

- A biohazard symbol sticker peeling off the bin lid.

- A cleaner wearing no PPE pushing a mop bucket past the bin.

- A liquid drip trail on the floor leading from the bin toward a fire exit.

- A small digital panel on the wall flashing “Negative Pressure Room Fault”.

Interpretation Focus Areas

The picture suggests poor segregation, untrained staff, inadequate infection-control systems, and digital ventilation alarms indicating risk of airborne contamination.

SCENARIO 3 (LO3 – Ecological Risk Assessment and Environmental Controls)

Image Description

The picture shows an industrial yard during rainfall:

- A small chemical spill is spreading downhill toward a storm drain.

- A faded “Environmentally Sensitive Area – Drain to River” sign is nearby.

- Two workers attempt to hose down the spill instead of containing it.

- The spill kit box is visible in the corner but unopened and covered in dust.

- A digital weather station display shows “Heavy rain alert – next 20 minutes”

Interpretation Focus Areas

The image clearly shows behaviours that cause watercourse contamination, misuse of equipment, and failure to consider environmental sustainability.

SCENARIO 4 (LO4 – Ergonomic Engineering Controls)

Image Description

The picture shows an assembly area with:

- A worker twisting to lift a load onto a shelf above shoulder height.

- A mechanical lifting arm is present but out of service, with a “Awaiting Maintenance”

tag dated six months earlier. - The worker’s stance shows excessive bending.

- A small digital workstation panel shows “Ergo Assist Offline”.

- Boxes are stacked unevenly on the floor, narrowing the worker’s movement space.

Interpretation Focus Areas

The picture reflects engineering failures, poor ergonomic design, equipment neglect, and unsafe human posture.

SCENARIO 5 (LO5 – Biological Outbreak Assessment)

Image Description

The picture shows a communal staff area in a food-processing plant:

- Several workers sit close together, wearing no masks during an active seasonal

outbreak. - A digital air-quality monitor on the wall displays CO₂ levels at 2100 ppm.

- A PPE dispenser is empty.

- The hand-sanitiser station has a handwritten sign: “Out of Stock – Use Water”.

- A worker visibly coughs while preparing to return to the production line.

Interpretation Focus Areas

The visual cues show poor outbreak control, high airborne contamination risk, failure to maintain hygiene supplies, and ineffective compliance culture.

SCENARIO 6 (LO6 – Chemical Hazard Failure Scenarios)

Image Description

The picture shows a chemical mixing room:

- A mixing tank gauge reads above the maximum fill line.

- A pipe connection near the tank shows a small vapour leak.

- The tank temperature display reads 76°C, which is above safe reaction limits.

- Emergency ventilation fans are off, with a digital error code showing “System Fault

34”. - A worker manually adjusts a valve while not wearing respiratory protection.

Interpretation Focus Areas

The image indicates severe risk of over-pressurisation, thermal runaway, ignition risk, engineering failure, and unsafe human behaviour.

SCENARIO 7 (LO7 – Accident Causal Analysis for Physical Hazards)

Image Description

The picture shows a warehouse storage area:

- Several boxes are stacked unevenly on a top shelf, one overhanging the edge.

- No pallet safety barriers or anti-fall mesh are installed.

- A worker stands on a pallet lifted by a forklift rather than using a mobile access ladder.

- Inspection tags on the racking are missing.

- A digital task screen shows “Order Priority: High – Deadline 12:00”

Interpretation Focus Areas

The picture shows behavioural, organisational, and structural failings suitable for domino or Swiss Cheese model analysis.

LEARNER TASK

The learner must select four scenarios from the seven provided and complete the following assignment:

- Describe all visible hazards, unsafe acts, unsafe conditions, missing controls, and digital system warnings.

- Explain what organisational, technical, cultural, or human-factor issues the image suggests.

- Identify all relevant UK laws, such as:

- Health and Safety at Work Act 1974

- Management of Health and Safety at Work Regulations 1999

- COSHH Regulations 2002

- RIDDOR 2013

- Workplace (Health, Safety and Welfare) Regulations 1992

- Environmental Protection Act 1990

- Lifting Operations and Lifting Equipment Regulations (LOLER)

- PUWER 1998

- Biological Agents Regulations

- Describe what must be done in the next minutes or hours.

- Explain engineering redesign, digital enhancements, cultural reinforcement, training,and sustainability measures.

- Discuss how a safety leader should communicate, influence, and build a culture that prevents recurrence.