Diagram and Photo Interpretation in Safety Systems

ProQual Level 7: Knowledge Tasks in Global Safety Performance

Table of Contents

Introduction to the Task

This task presents the learner with a set of detailed described images/diagrams representing realistic workplace conditions. Although the actual images are not provided visually, each image is described with enough clarity to allow a high-level interpretation similar to real-life safety inspections.

The purpose of this task is to:

- Strengthen hazard identification and interpretation skills

- Analyse deeper organisational, cultural, and sustainability issues revealed by site conditions

- Connect observations to global safety challenges (climate, supply chain pressures, economic constraints, etc.)

- Assess psychological, behavioural, and cultural implications

- Propose sustainable and evidence-based corrective actions

- Evaluate performance metrics and determine safety-investment ROI

This task mirrors the type of advanced analytical work expected of senior HSE leaders, auditors, and strategic risk managers.

Scenario Overview

You are a senior HSE auditor conducting an announced site inspection at a multinational manufacturing facility. The organisation operates in the metal fabrication, tooling, and assembly industry. As part of the audit process, you are given a series of photographs and diagrams (described below). Your job is to:

- Analyse what each image indicates

- Interpret underlying safety culture, sustainability, and psychological/organisational issues

- Identify non-compliances, risks, and defects

- Recommend strategic corrective measures

- Link findings to global trends and pressures impacting performance

Photo / Diagram Set (Described)

Below are the detailed descriptions of the site images you will be analysing:

Image 1: Waste Disposal Area Behind the Manufacturing Facility

The photo shows:

- A fenced waste storage zone with overflowing bins

- Mixed waste: metal scraps, plastic wrappers, paint containers, oily rags

- At least three bins are unlabelled

- One container with a chemical hazard symbol is lying on its side leaking fluid

- Two workers walk past the area without noticing the spill

- Grass around the fence appears dead and discoloured

- A faded “Sustainability Commitment: Zero Waste to Landfill” sign is visible but partly torn

- CCTV camera above the waste area appears broken

Image 2: Welding Bay Environment

The photo shows

- A welder performing grinding without face shield and apron

- Welding fumes visible in the air but the extraction arm is pulled back and unused

- Multiple flammable liquid containers placed near a spark source

- Safety posters are on the wall but covered with dust and outdated (posted 7 years ago)

- A production supervisor stands in the background talking on a mobile phone, not observing the work

- A digital thermometer on the wall shows 37°C due to poor ventilation

Image 3: Worker Wellbeing and Rest Area

The photo shows:

- A small, dimly lit break room with no ventilation

- A handwritten note on the wall: “No long breaks due to production targets”

- A cracked water dispenser with a bucket underneath to catch drips

- Three workers sitting with exhausted expressions, one rubbing their shoulder in pain

- Psychosocial support hotline poster is faded and unreadable

- First aid box is locked and no responsible person is present

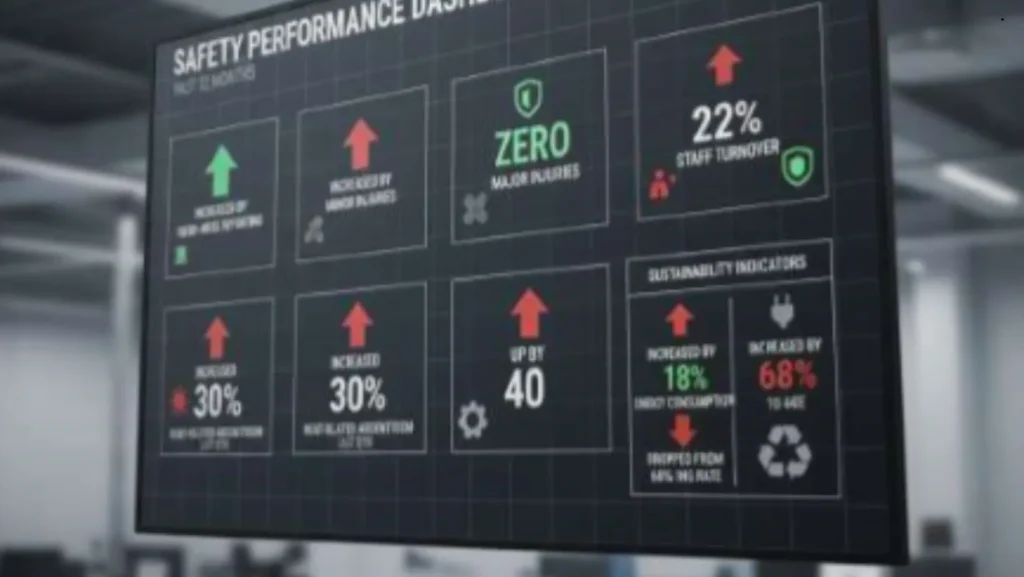

Diagram 4: Safety Performance Dashboard (Past 12 Months)

The dashboard shows:

- Increase in near-miss reporting by 45%

- Increase in minor injuries by 15%

- Zero major injuries

- Staff turnover increased by 22%

- Heat-related absenteeism increased 30% in the last quarter

- Maintenance backlog up by 40%

- Sustainability indicator: Energy consumption increased by 18%

- Sustainability indicator: Recycling rate dropped from 68% to 44%

Task Instructions

Study each described image carefully and answer the analytical questions below. Your answers must include Level 7 depth—strategic interpretation, system-level reasoning, and connections to global safety culture and sustainability trends.

Task Questions

Section A – Observation and Interpretation

1. Image Observations

For each image/diagram, list all observable hazards, non-compliances, behavioural indicators, and safety culture signals.

Your observations must cover:

- Physical hazards

- Sustainability failures

- Psychological health indicators

- Leadership and cultural elements

- Evidence of system weakness or organisational drift

Section B – Linking to Global Safety Culture and Sustainability Issues

2. Global Influences Analysis

For each image, explain how global issues may be contributing to the problems observed, such as:

- Climate change impacts on worker health (e.g., heat stress)

- Global supply chain pressures affecting maintenance and PPE availability

- Economic constraints affecting workforce morale

- Cultural diversity challenges in multinational settings

- International sustainability trends and ISO 14001 expectations

Provide at least two global influences per image.

Section C – Strategic Corrective Measures

3. Corrective Actions (Technical + Organisational)

For each image, propose high-level corrective and preventive actions, including:

- Engineering controls

- Sustainable waste/energy improvements

- Leadership and behavioural interventions

- Psychological health support measures

- Training and awareness improvements

- Systemic changes in management reviews, procurement, and KPIs

Actions must reflect integrated thinking between safety culture, sustainability, and performance.

Section D – Safety Performance and ROI

4. Performance Measurement

Using the safety dashboard (Diagram 4), answer:

- What do the trends indicate about the facility’s current safety culture?

- Which leading indicators show early signs of deeper problems?

- Calculate how a 10% reduction in absenteeism could financially impact productivity if the average daily worker cost is £180 and current heat-related absenteeism results in 180 lost days per quarter.

(Show your calculations.)

5. Investment Return (Strategic ROI)

If management invests £25,000 in:

- Upgraded ventilation

- Heat-stress monitoring sensors

- Workforce wellbeing programme

Explain:

- What safety performance improvements should be expected?

- Which sustainability KPIs will also benefit?

- How can the organisation calculate ROI beyond financial metrics (e.g., reputation, retention, global compliance)?

Section E – Psychological Health and Injury Management

6. Psychosocial Risk Evaluation

Using Image 3:

- Identify key psychosocial hazards

- Explain how these hazards impact injury rates, staff turnover, and long-term performance

- Recommend a psychological injury management framework aligned with global best practices (e.g., ISO 45003)

Expected Deliverable

Learners should produce a comprehensive, evidence-based analysis (1500–2500 words recommended) that demonstrates:

- Advanced interpretation of visual data

- Understanding of global influences on safety culture

- Integration of sustainability and wellbeing into safety systems

- Strategic action planning and ROI justification

- Professional-level depth aligned with Level 7 leadership competencies